KTECHNO

|

|

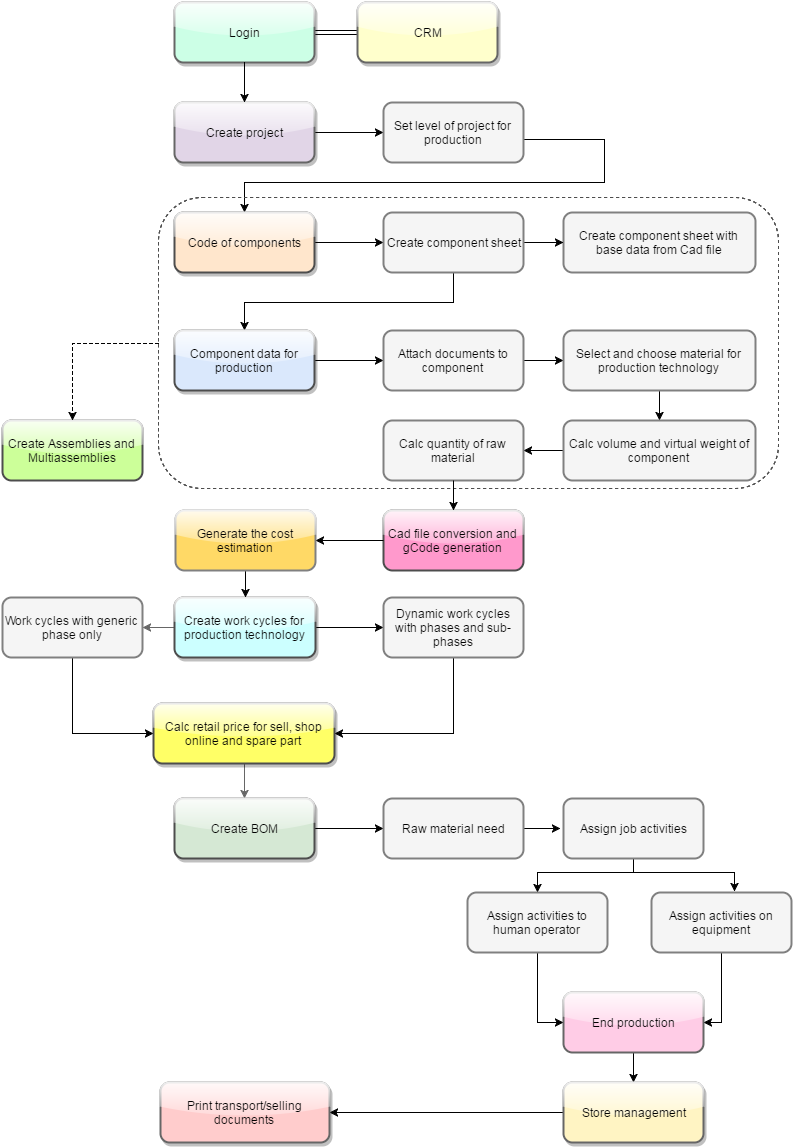

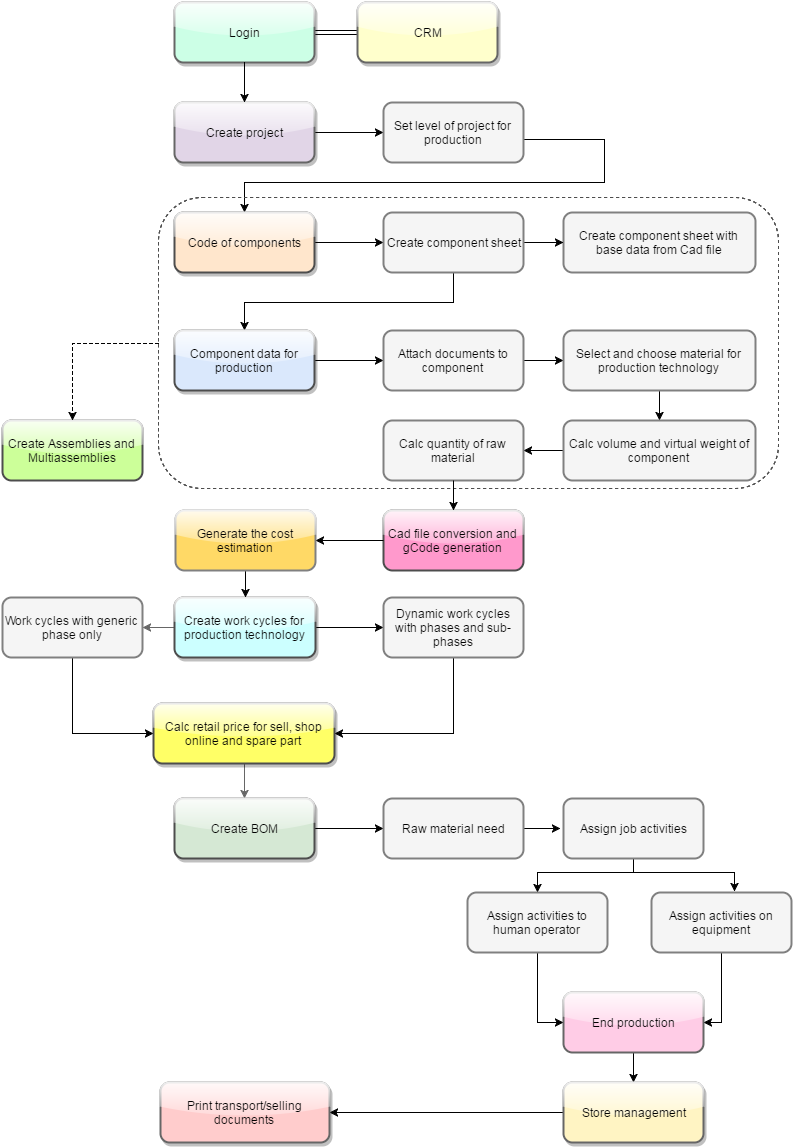

KTechno is customized for each user, the login procedure permits to configure the user profile so he can use only the its functions. If KTechno is installed in a Lan, every user will can use different workstations always with its customized profile. The login is possible also reading a special barcode in a card with a standard barcode reader.

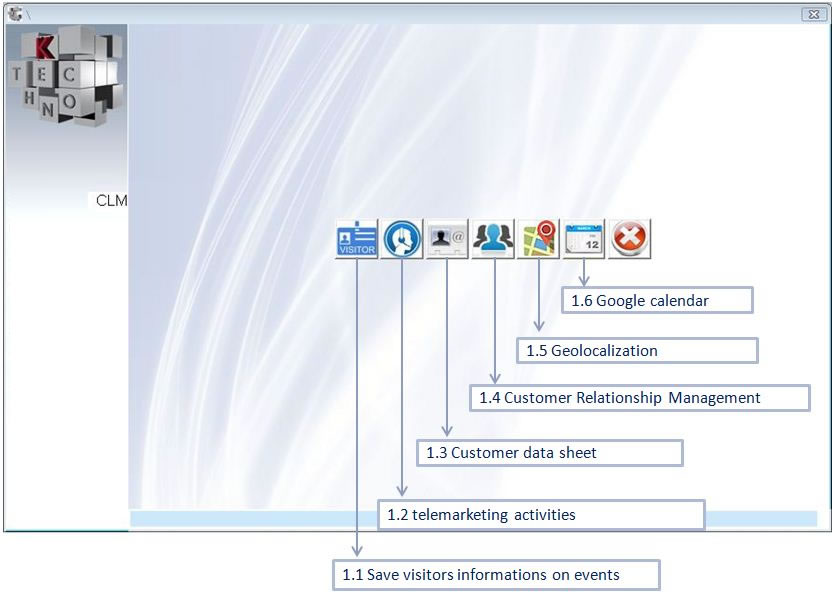

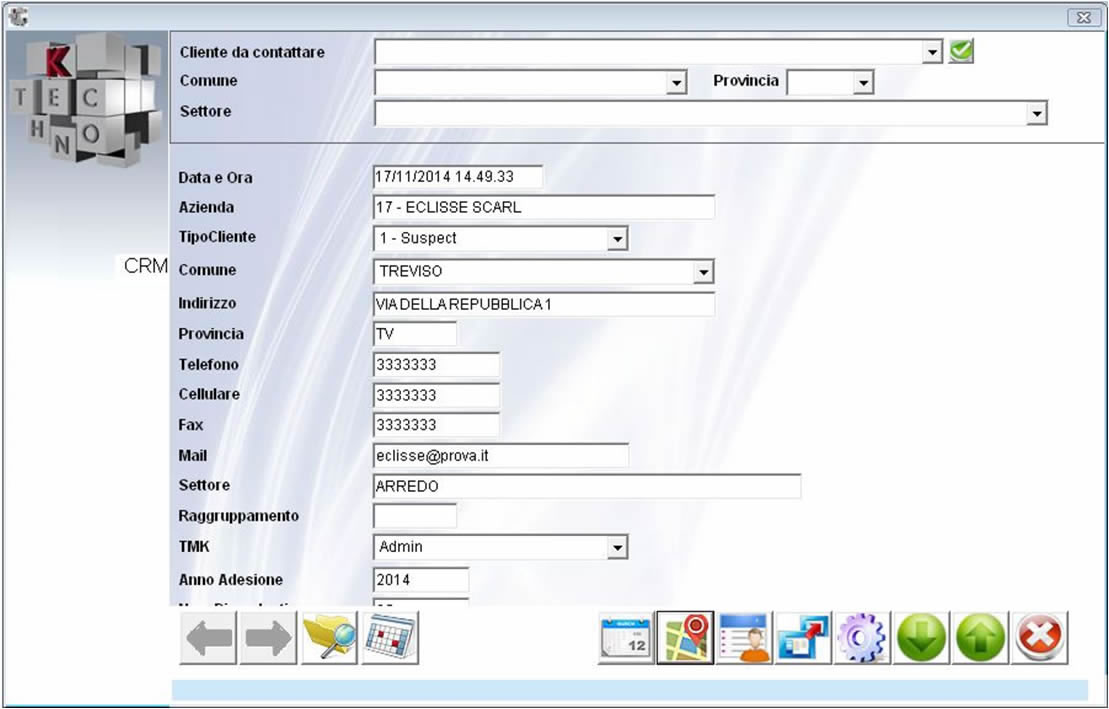

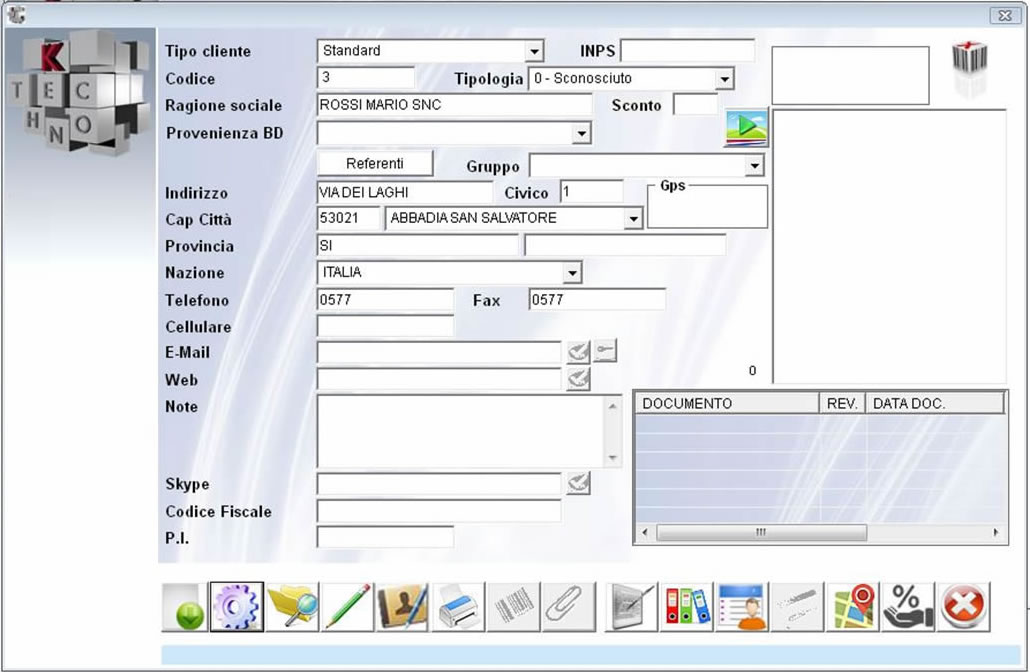

KTechno includes a complete CRM interface that allows you to record and manage any kind of information about its customers, acquired or future, telemarketing proposals, conversations, messages, purchases carried out and any other information relevant to the customer contacts in order to get under control every situation. Knowing what a customer has purchased and when it will be used to carry out targeted marketing proposals for product in use, and promptly inform the client about any upgrade and news. The CRM interface allows you to locate clieni with GoogleMap and make such information useful for activities agent that can manage information and program the best strategy for any appointments. The registry allows you to save all kinds of informations, contacts, phone, web, skype etc. and georeferencing automatically the contact for the best Customer LifeCycle Management.

This function need to save data of potential customers

This mask allows to save each kind of informations, data contacts, phones, web, skype and georeference of contact to never lost data. It is always important to manage all customers processing data to send right message to right persons. If you wamt to make a marketing activity, or if you want to send a news message to inform about a new product.

The CRM interface allows to localize customers with GoogleMap and optimize the activity of agent that will can best organize its appointments.

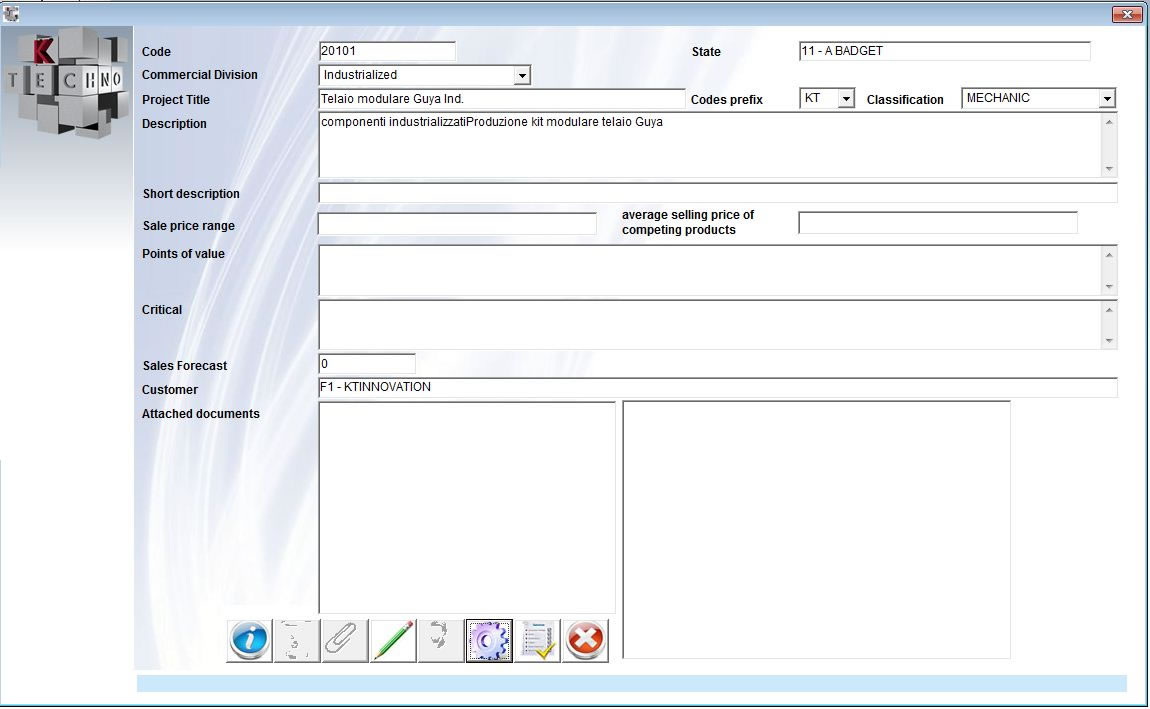

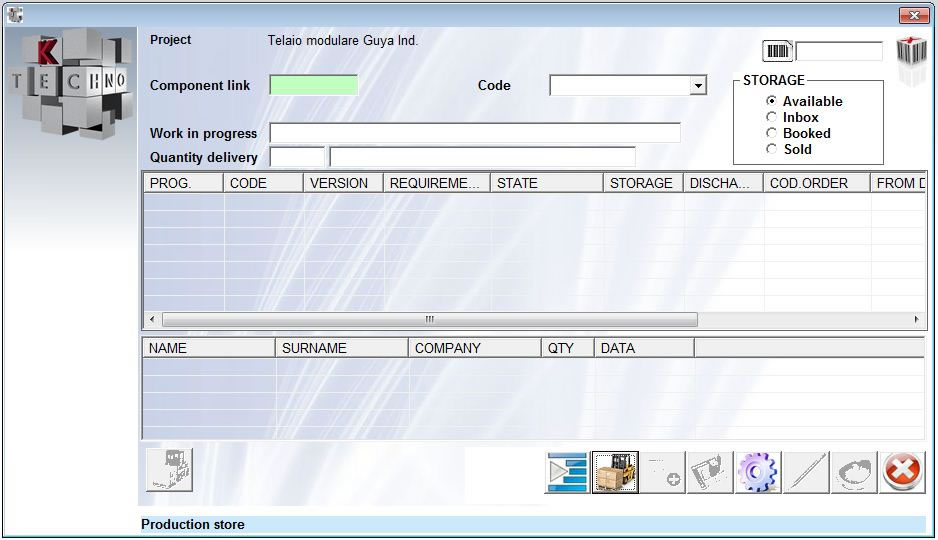

Form to create project data and allows it to pruction

Each product information always refers to a project that is, in practice, the 'container' of information in which you can select the main data of the project to be developed, his owner, its characteristics economic as well as encoding and belonging in order to catalog the activities of production very clearly. The project is the "head" of the product and is used to enable or not the data flow for manufacturing. The informations, all as optional, are used to identify the membership and the basic characteristics of the components to be produced enabling or not the production process.

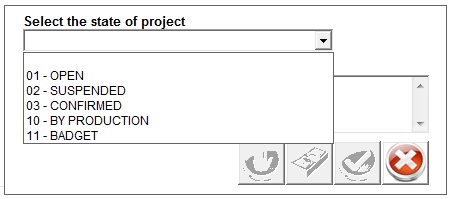

In a network installation environment, the use of state levels is to be understood as the main function where the various departments, involved in company, involved in the development of new affixing activities, from R&D department, to development to production and logistics department, their status levels needs to confirm the progress of the project and make it producible or not.

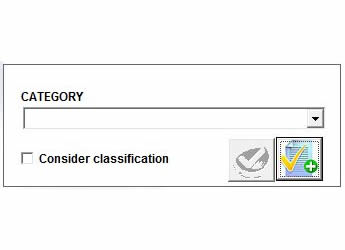

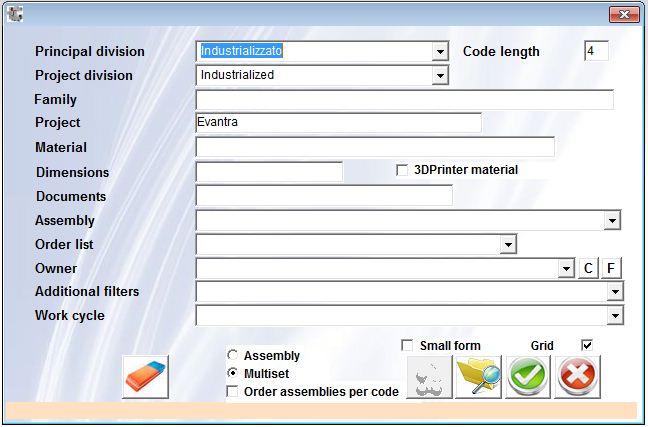

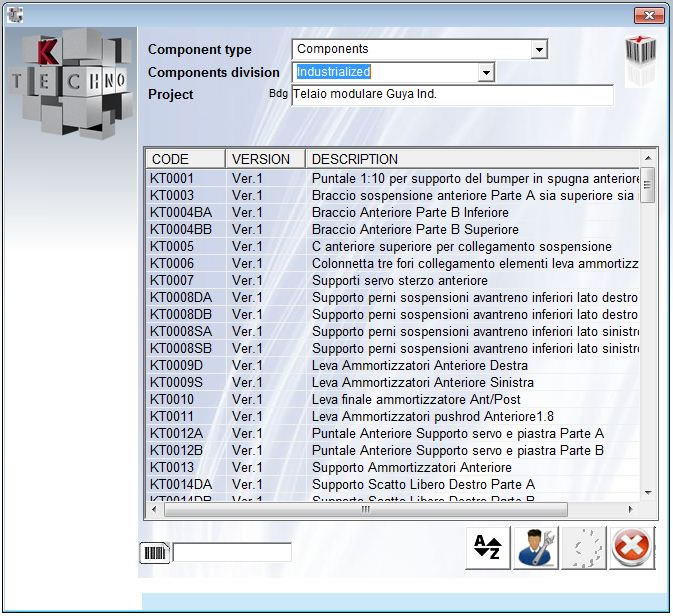

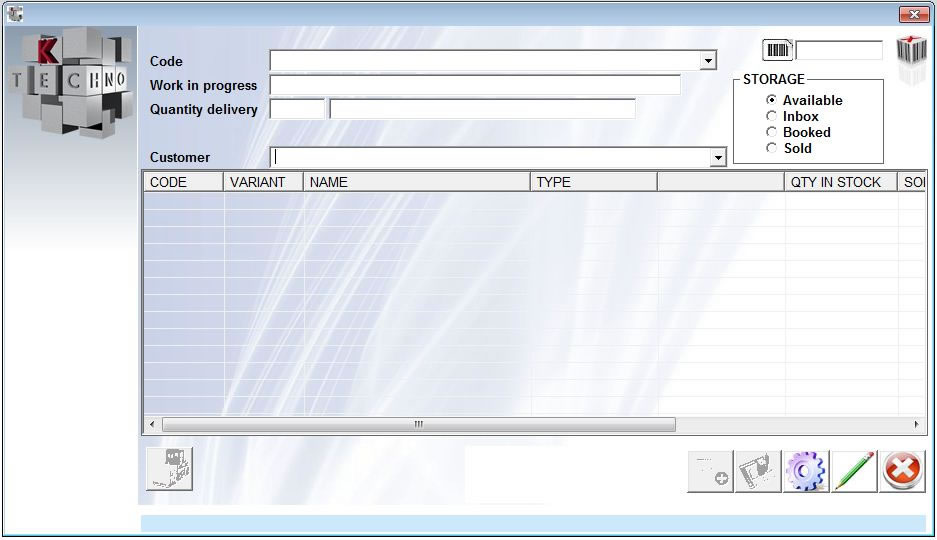

Start selection

The classification of the components are defined for different important items: the draft code of belonging, the membership division (industrialized, commercialized, buyed), associated materials, owners and so on. Can possible select the management of the components according to the needs of the moment optimizing the search lists and making easier the search of components to manage.

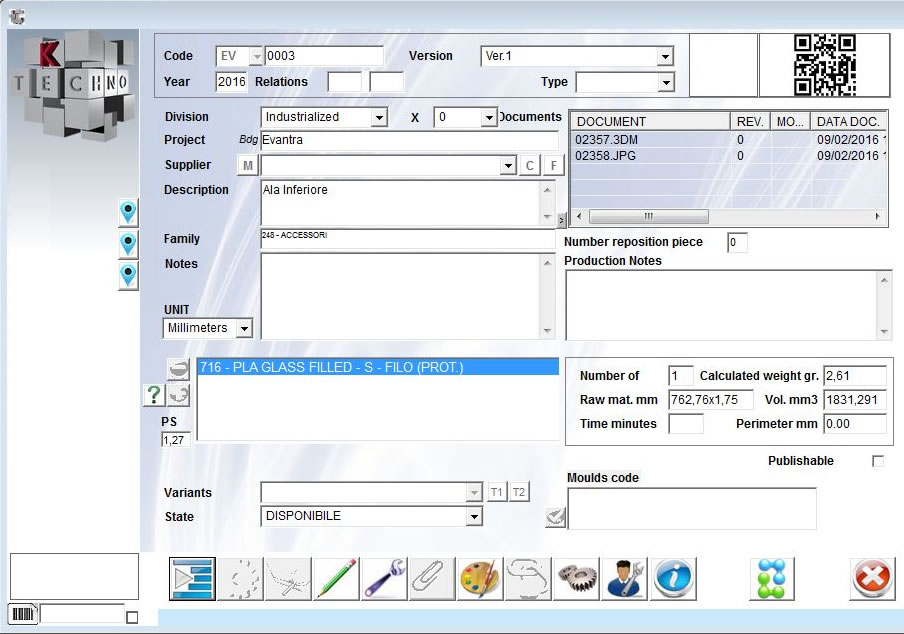

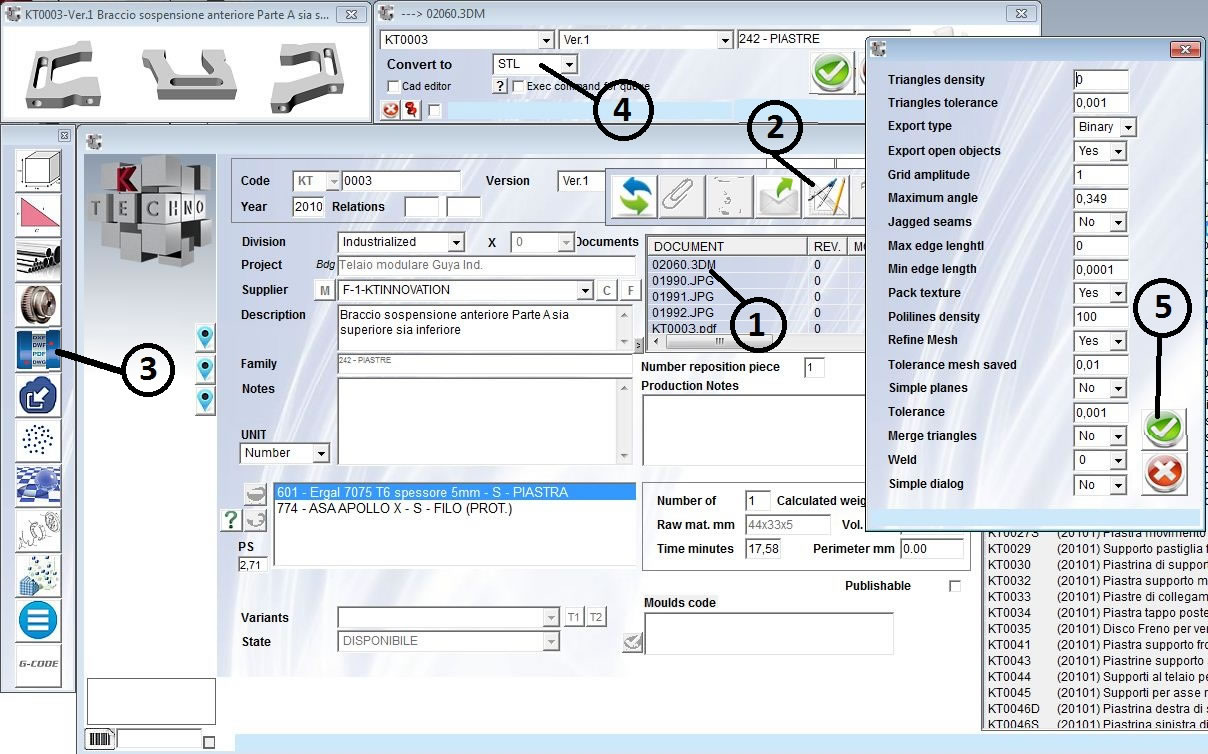

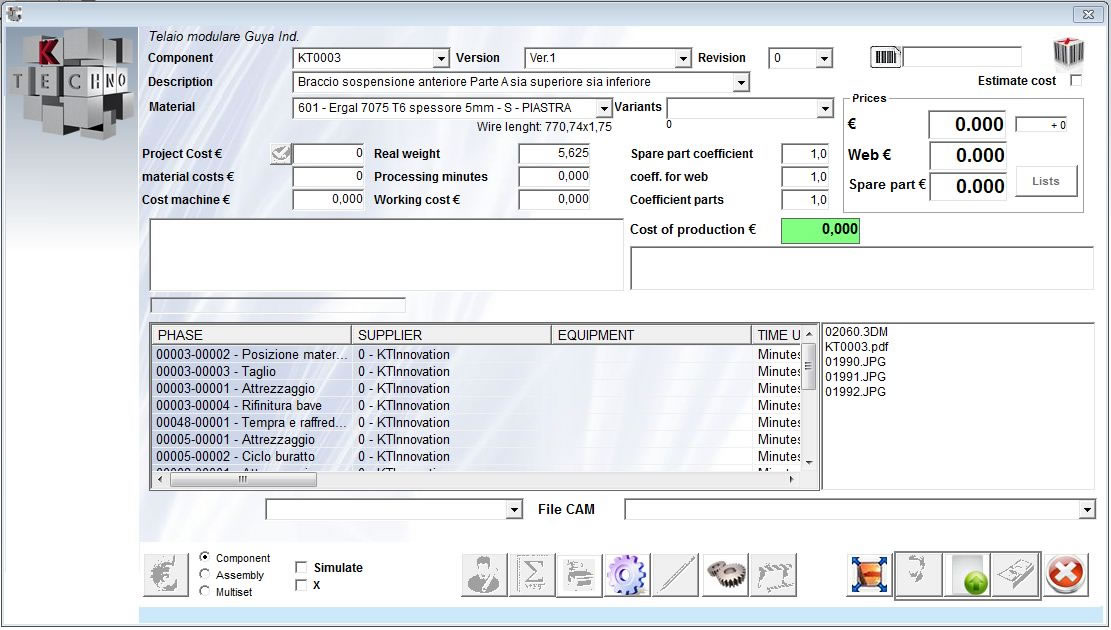

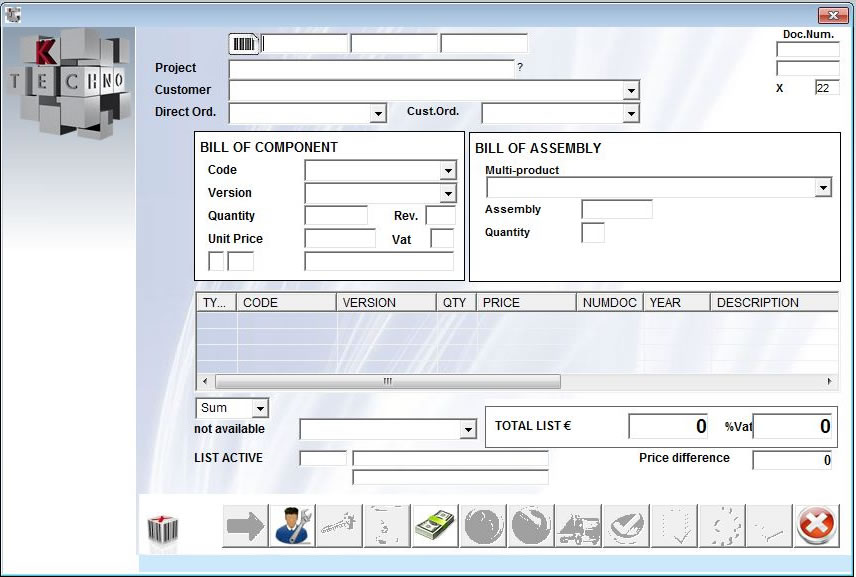

This form needs to define all production data and documents attached

Coding involves the use of numerical codes, number with prefix code, alphanumeric, autoincremental or for specific rule.

The components are identified within the system by the specific coding and being distinct production. They can be combined with an additional specific code that is created by the user rules and accompanying the product for sales processing (storage, shipment).

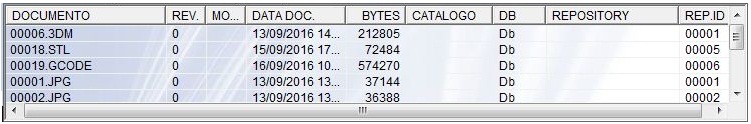

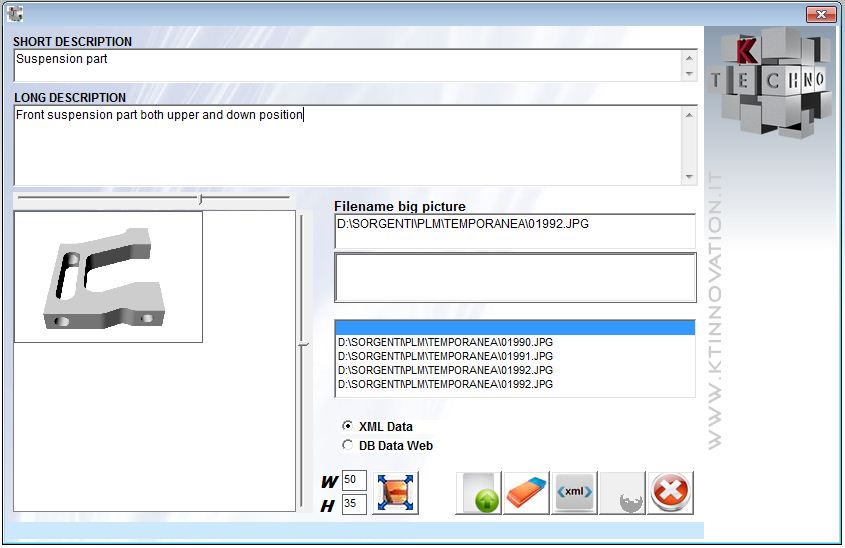

You can insert descriptive notes and attach any type of document relating to the same component, by its CAD design, images classified for catalogs and preview, generic documents, files conversion, gcode, Word, Excel documents and so on. The special feature for each document is that it is subjected to revision control so that is never lost information and all is always secure for the identification of the correct data to be produced.

From this function, KTechno checks that the design CAD is paired correctly encoded and makes possible Cad direct calculation from the interface to receive values ??of volume, raw material necessary for the production, production time and, if a material is associated, calculates the virtual weight value recordable separately with the real balance weight.

Each component can be combined and declared producible in different raw materials with different technologies, this case will be combined with the appropriate working cycles and it will be possible to define a component simultaneously producible, for example, with milling or 3D printing tecnology.

KTechno is able to generate gear geometries and read gCode data for reverse engineering by recreating the point cloud.

During the job order it is able to facilitate nesting in the design to create multiple machining operations.

"KTechno recognizes all types of geometry, both 2D and 3D, activating the appropriate calculation functions and then performing volume calculation, object weight, area or perimeters, recognizes the holes by associating thread data

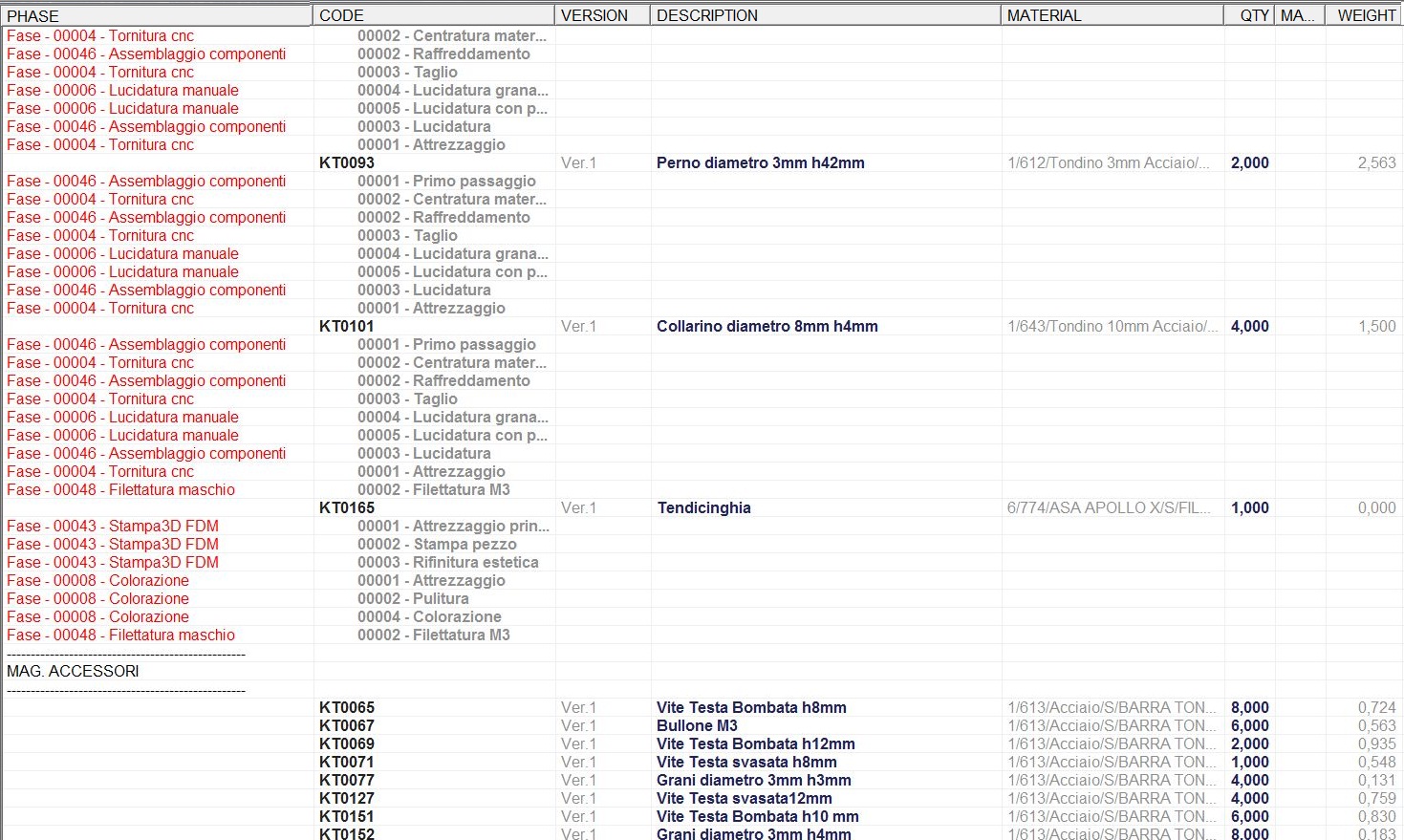

Check every operation about the components to produce, materials, work cycles, customizations.

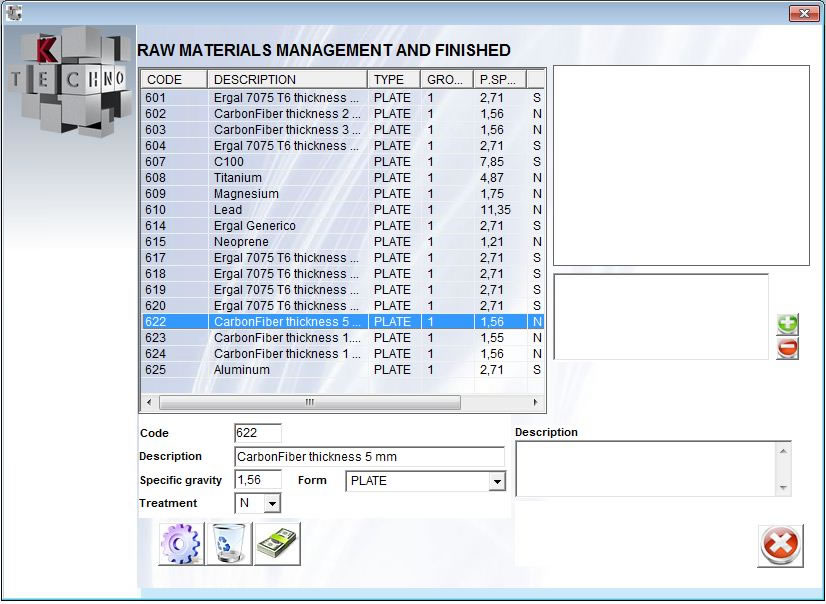

KTechno ranking the materials by type, separating raw materials from purchased accessories. Raw materials include information as density and suppliers data for commercial order All Raw materials are classified by category (Plate, bar, filament, liquid...)

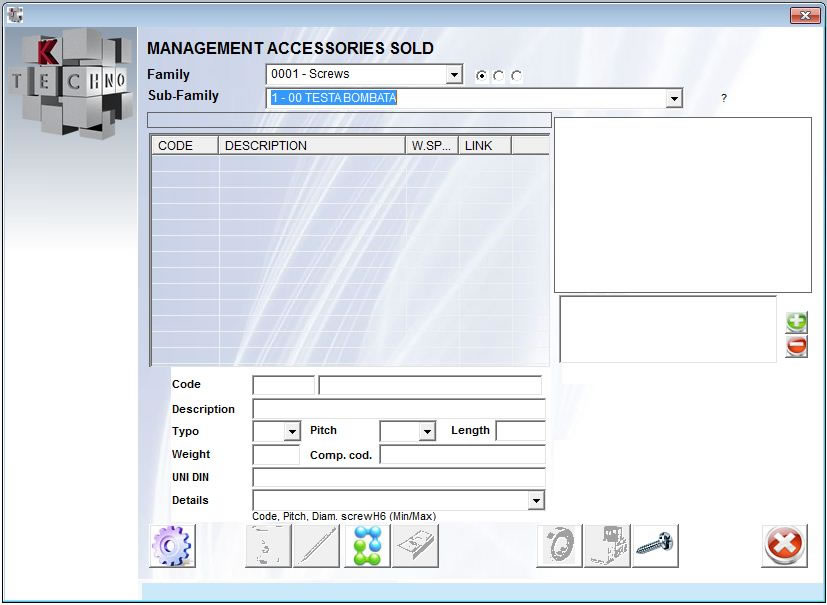

KTechno ranking the materials by type, separating raw materials from purchased accessories. Accessories are classified by type and can have a direct link to the component sheet to facilitate the purchase in the BOM.

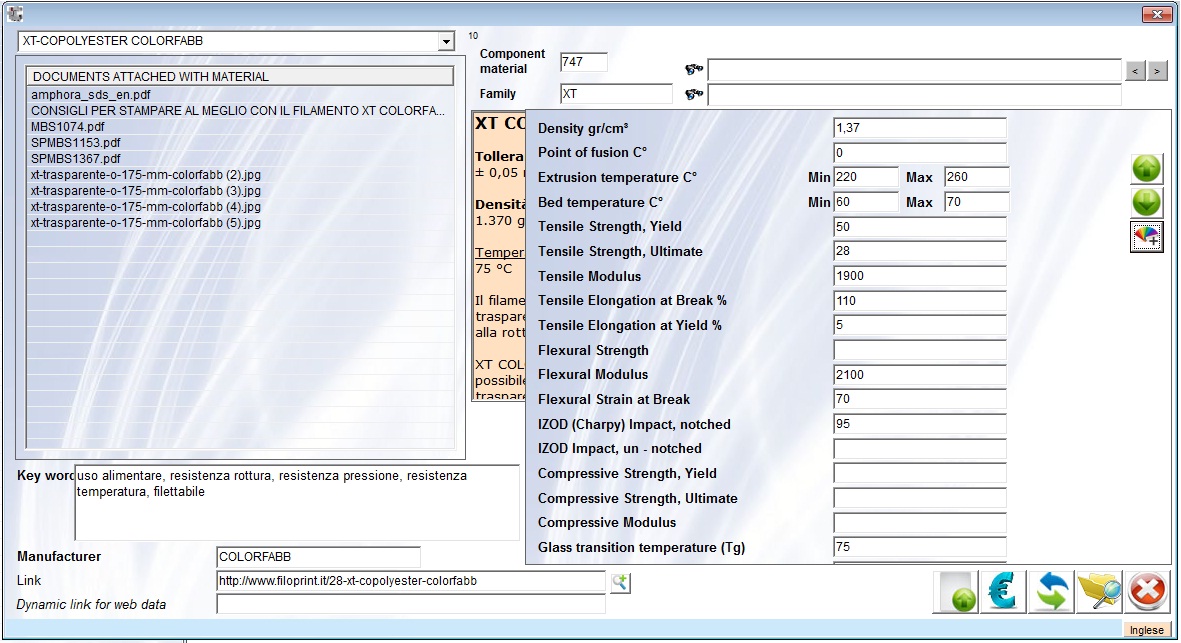

KTechno include a database of filaments with descriptions and technical data, datasheet, description documents and sample images. All filaments are classified by manufacturer, family and a series of Tags data that permit to describe each component and help user to select the best filaments for the characteristics of component comparing also the cost differences. From this mask is possible to create the order of material to distibutor or selected manufacturer.

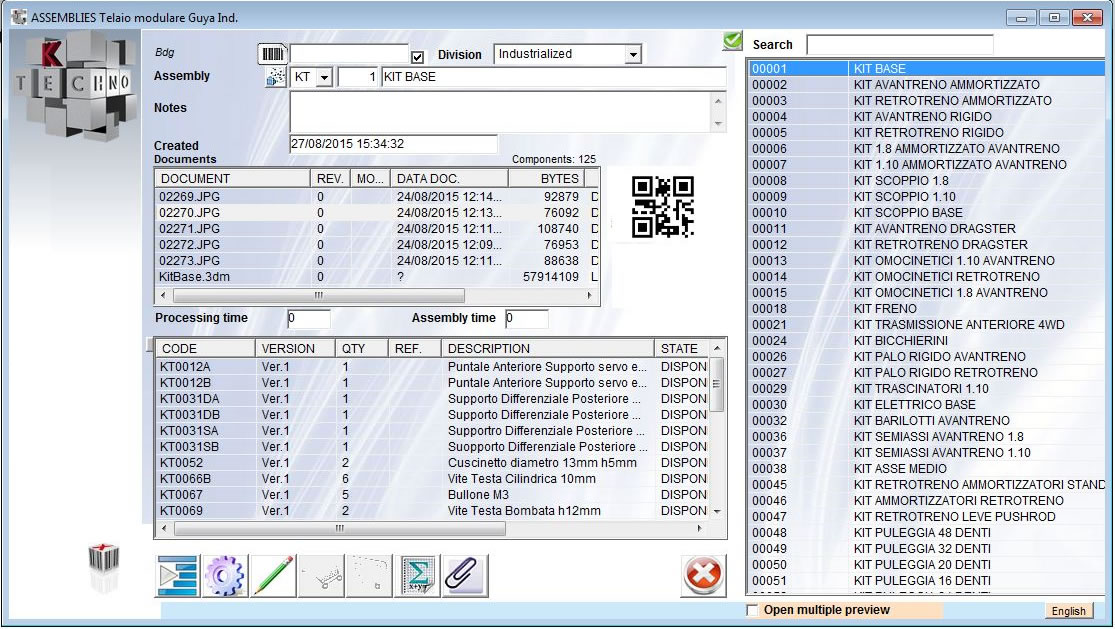

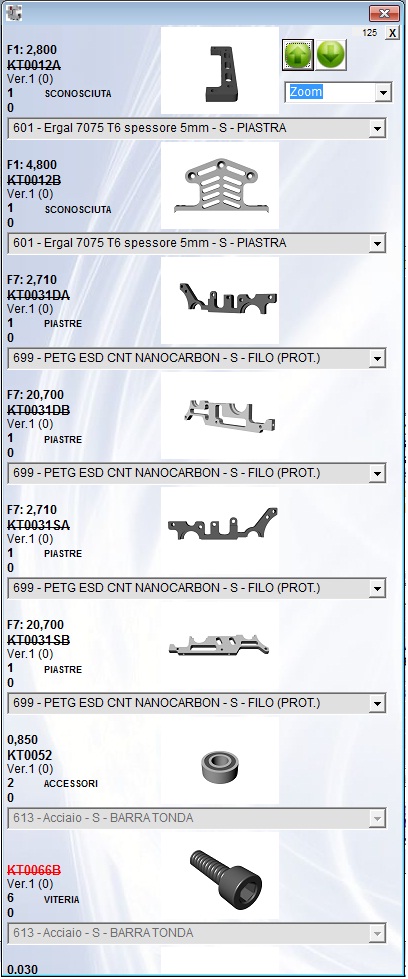

Component sheet data permit to create Assemplies and MultiAssemblies. During the productionwill be extracted the data of single components considering all customization rules such as dependencies,substitution, raw materl preferences, quantity rules and so on.

MultiAssemblies are the same of Assemblies but descrive very complex product with the same production rules (dependencies, substitution, raw materl preferences, quantity rules and so on. Each assembly is coded by the system considering code project and category and every kind of document (as the componensheet) can be attached.

The components included on assemblies and MultiAssemblies can be show and described in a practice list from where is possible to make some calculation such as total weigh information or total cost with materil selecting. Useful to make a cost estimation.

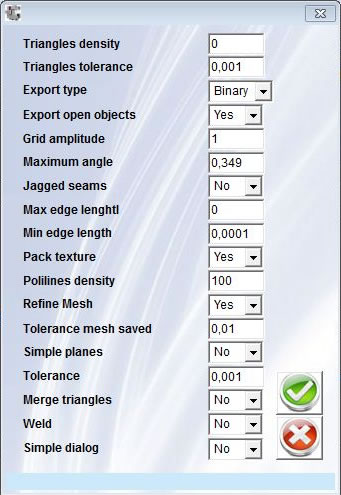

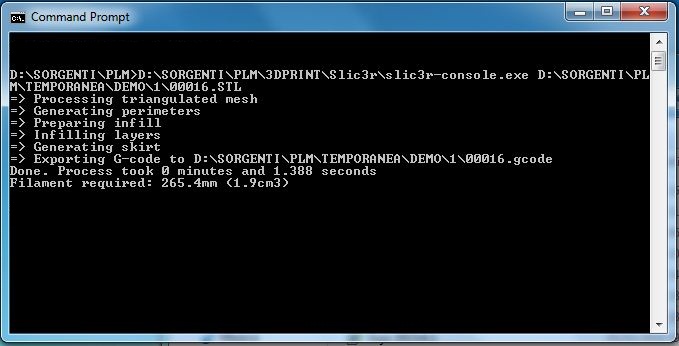

To produce a component, need to generate gCode file. KTechno help to process the Cad file and operate to convert in STL, IGS, STEP depending on Cam. For 3D printing the gCode file is created manipulating external slicing software.

SELECTIONS ORDER

1. Select component Cad file do you want to convert

2. Select from the console for attached documents, the function for Cad file

3. Select conversion file in STL format (for 3D printing) or others formats depending to CAM

4. After STL conversion (or others formats), KTechno ask for gCode creation

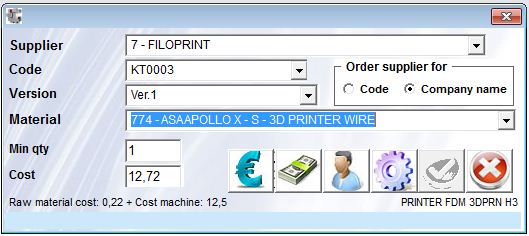

KTecno help user to select the best material to produce a piece and permits, for each material selected to calc a cost estimation considering both the raw material cost and equipment costs. All documents attached, can (chosen by the user) be saved internally o n the database or can be maintained in an external repository maintaining all security condition on revision and update control.

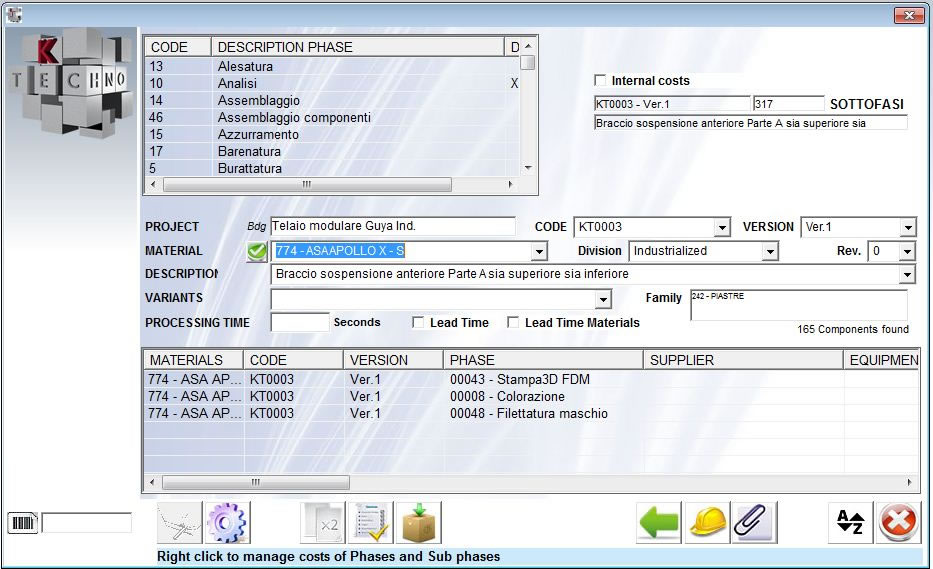

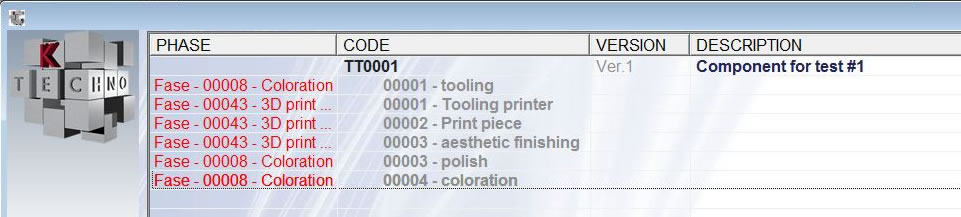

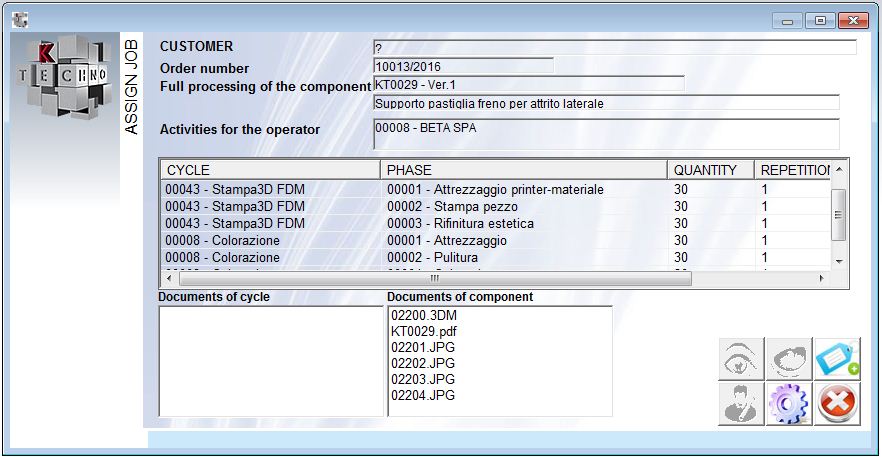

Each components, depending to selected material che have work cycle described considering both generic cycles or phase and sub-phase cycles. The complete description data permits to manage time production, lead time, costs and so on to describe each phase per each cycle. As the component sheet can be possible to attach different documents to best describe the job (assemblies instruction, images and so on)

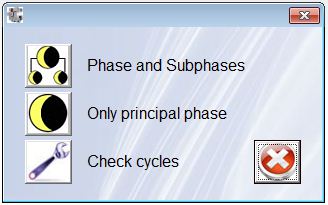

KTechno permits to select simple type cycle or cycles with phases and sub-phases that permit a more detailed description of each job activity.

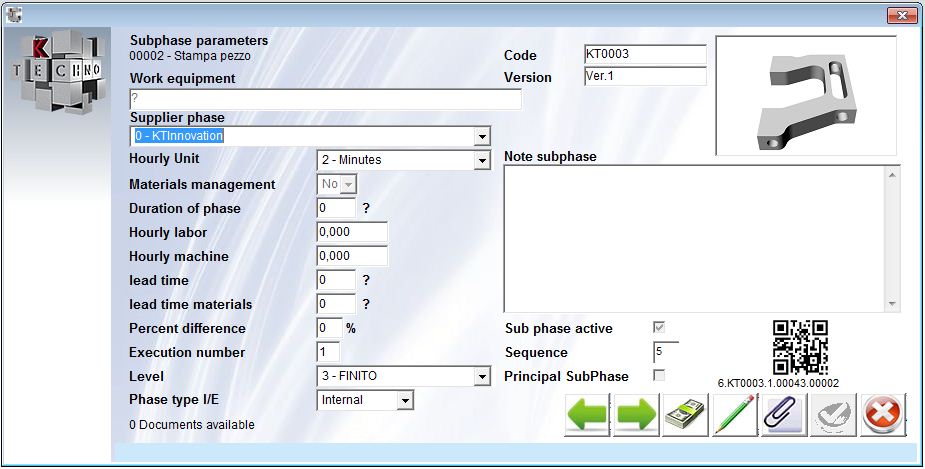

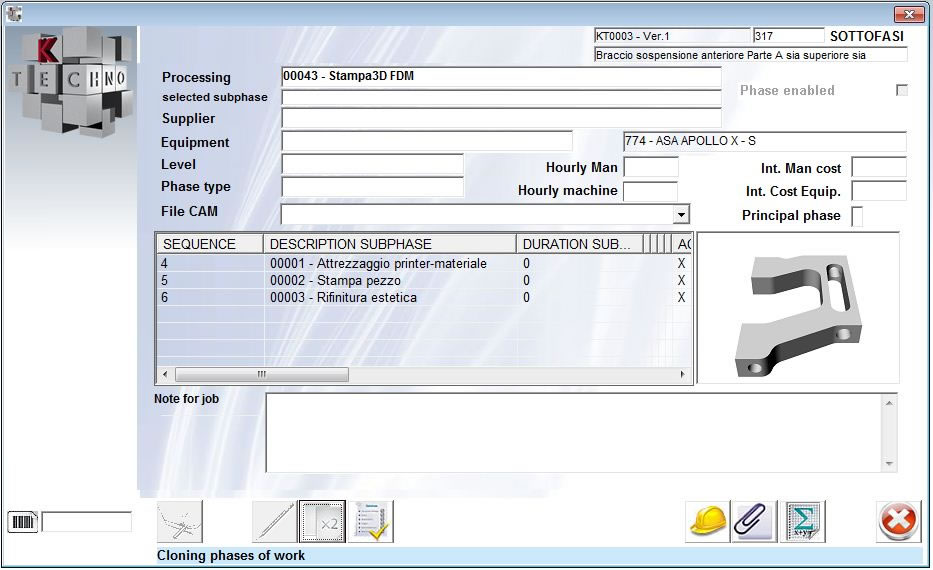

Relating to work cycle with phases and sub-phases, this mask permit to manage all kind of data need to describe each activity, document attachement is useful to add images and document to describe the job for the operator. Each subphase is coded with a barcode. Each cycle or sub-phase can be set active or inactive to optimize the control of the total or production cost.

If you select the use of sub-phases, KTechno allows to describe the operations to be carried out separately for each technology selected, by enabling or disabling individual entries can be dynamically manage production costs in the BOM.

For a complete management of the final customer price, KTechno allows you to manage the individual cost component splitting up the various items to be considered in the calculation of the total production cost. Cost of materials, human cost labor and related items allow you to itemize and manage the final cost with business cycles selected. Can be also distribute in the production cost the cost for design considering the total value or its percentage.

The final price to the customer is calculated by applying external user-customizable formulas to calculate separately The basic sale price, a sale price for an online shop and priced as spare part.

The designers who need to quickly communicate new ideas on the Web, KTechno offers the possibility to build a specific data flow thsat can be sent to a news web space.

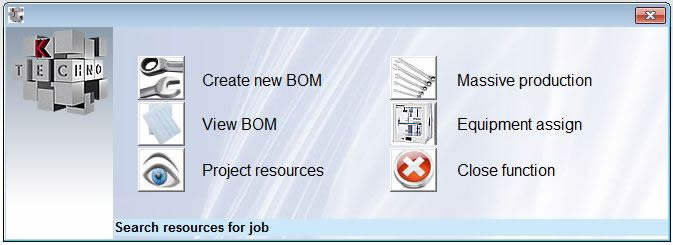

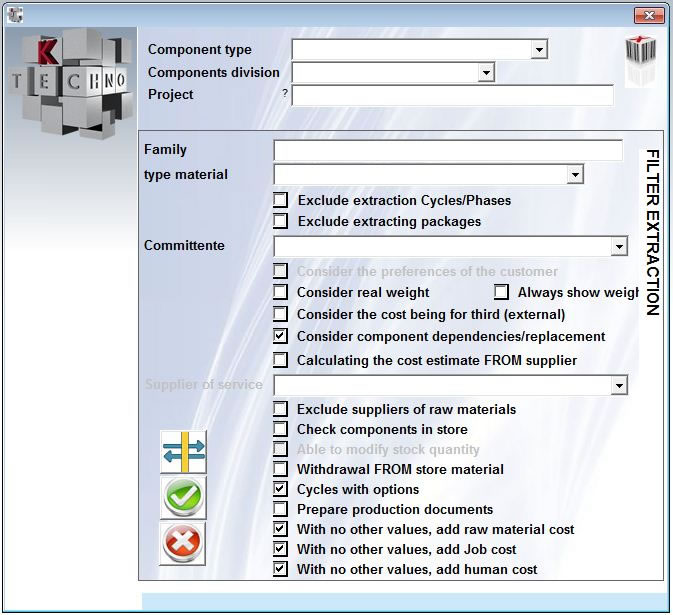

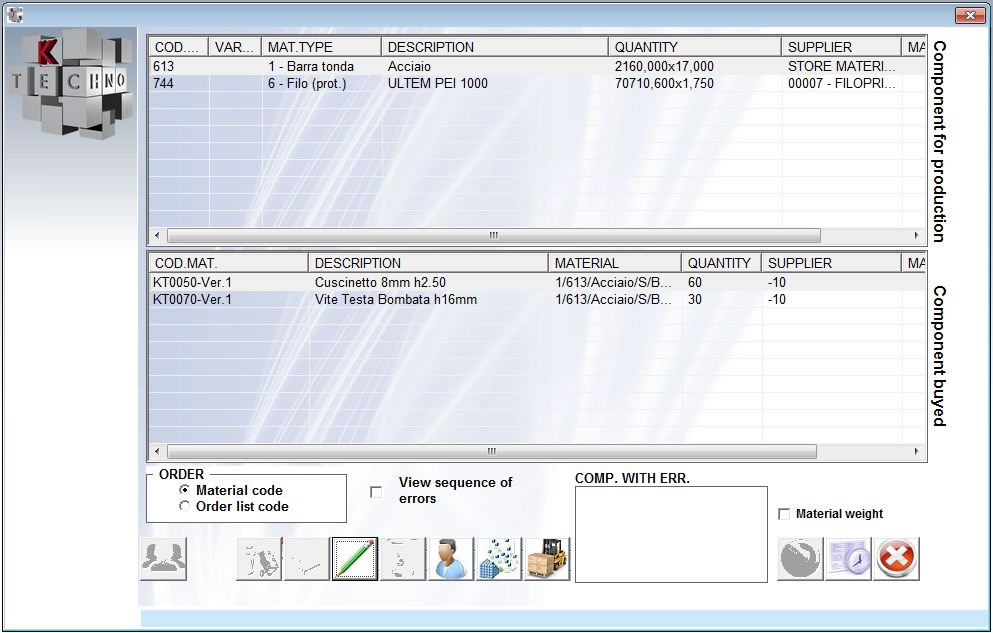

This form show the flow data when the Bom is created, we can generate the component list and work cycles for that Assembly or Multiassembly and needs to extract all data (quantity, volumes, raw materials) for production.

From this screen you can select:

It is possible, indifferently, create production BOM for single components, assemblies or multiassemblies.

Each BOM can be customized with the user preferences. If the user is not able to some features (for example costs data) this values will not be show.

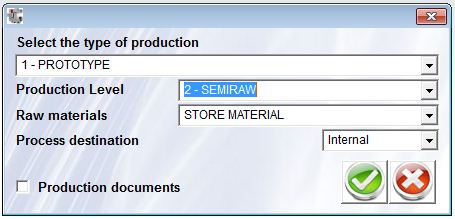

Launching new BOM, KTechno ask to select the type of BOM must be create, Quality level of final product, how to withdraw the raw material (from internal store or for external order) and the preferences for the job activity (internal or job for suppliers).

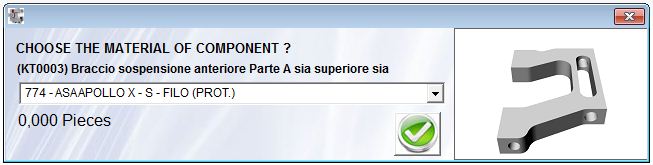

If the component is described with many raw materials (and different technologies), KTechno ask the material preference to produce the piece, this condition will select the correct wotk cycles list.

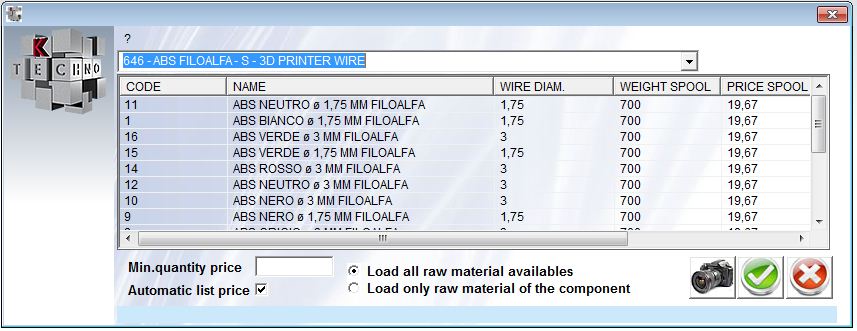

If the selected raw material is a filament for 3D print, KTechno show the option mask to select the correct variant of filament.

Calc the total or raw materials and accessories need for selected production. This form allow to create the order request to each supplier and assign the job to an operator or directly send data to equipment

If the production BOM hasn't lock in execution (for example due for data not found), a grid is open to view all data of BOM. This BOM is temporary until user confirm it, if the user cancel the operation, the data are deleted. Confirming the BOM KTechno make the calculation of raw material requirements depending by work cycles selected.

If the production BOM hasn't lock in execution (for example due for data not found), a grid is open to view all data of BOM. The BOM of an assembly is grouped for division tipology of components for an easy and quick data management. This BOM is temporary until user confirm it, if the user cancel the operation, the data are deleted. Confirming the BOM KTechno make the calculation of raw material requirements depending by work cycles selected.

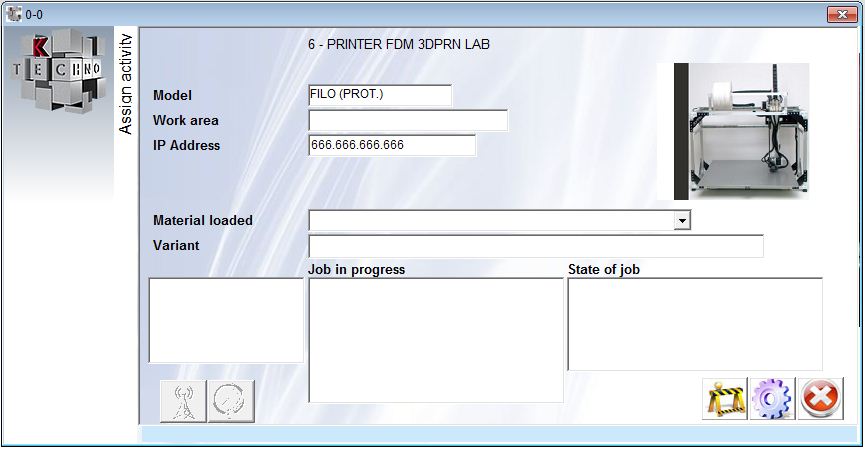

KTechno allow to save the informations about equipment to have a best possibility on its management.

This form allows to create the job queue for equipments and send to right machine the necessaries documents (Cad draw converted, gCode) for production.

Assigne job to uman operator

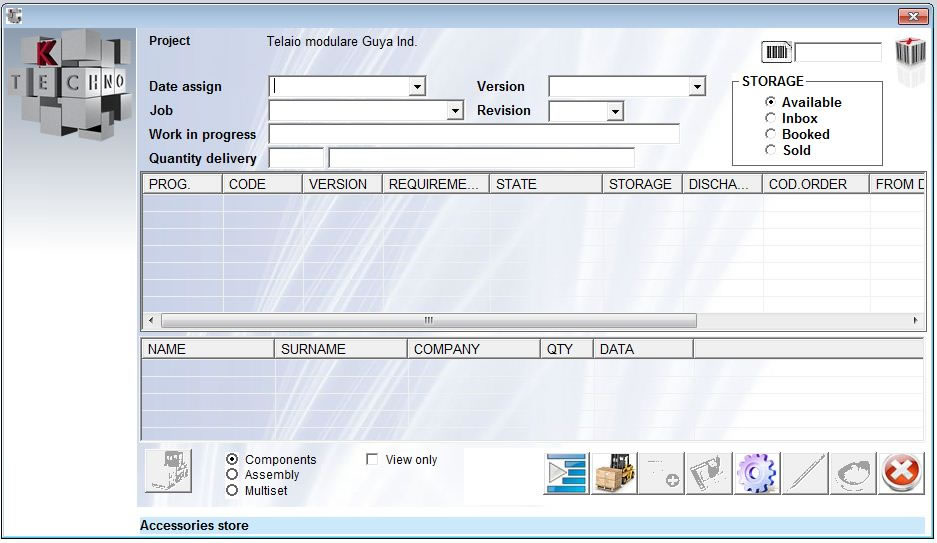

The store management allows you to manage inventory of accessories, raw materials and, of course, the production. When a BOM is closed and completed, automatically it generates a stock inventory which need to produce documents for delivery to the customer. No accounting is done, the function simply calculates the residence time of the product in stock.

Accessories store allows to manage the stock and if need to unload for selling or normal use and check the minimum quantity.

This funzion was made to control the stock of raw materials, particular for filaments 3D to sell 3D print filament directly. Useful to manages the minimum quantities in stock.

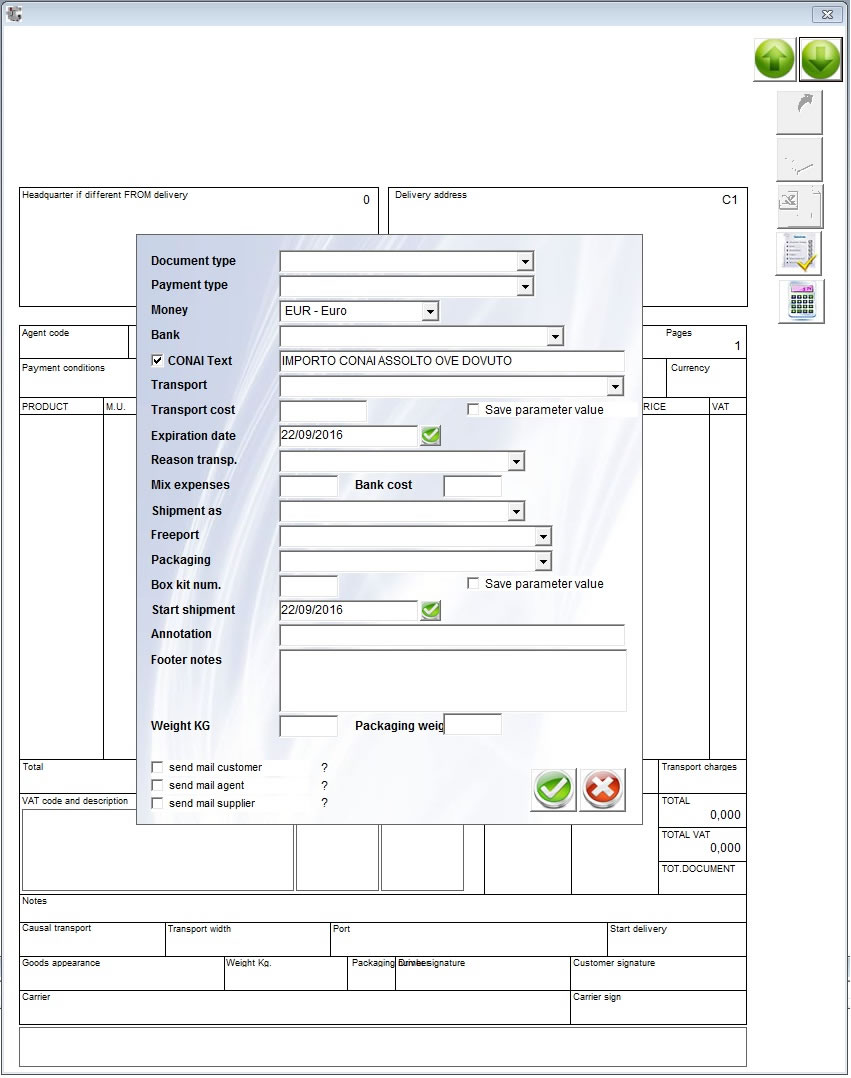

Automatically when an BOM is completed, a stock inventory is created, this section allows you to download the product created and deliver it to the customer with the appropriate sales and transport documents.

The end of BOM automatically create a stock inventory, this information need to delivery product to customer and consequent production of sales/transport documents.

KTechno is a technical software but permits to produce all the documents for transport and selling to customer (bill document, transport document) in different tipologies.